If you’re exploring innovative ways to produce high-quality medical components, metal injection molding medical in Boston, MA, offers unprecedented advantages that are reshaping the healthcare industry. Smith Metal Products is at the forefront of delivering precision metal injection molding solutions for medical device manufacturers, enabling complex geometries, superior material strength, and miniaturized parts that meet the rigorous demands of modern medicine. This blog will dive into how the metal injection molding medical process is transforming medical technology development, especially in this thriving biotech hub.methods.

What Is Metal Injection Molding, and Why Is It Ideal for Medical Applications?

Metal injection molding (MIM) is a manufacturing process that combines fine metal powders with a binder material to create a feedstock, which is then injected into a mold cavity. Once shaped, the component undergoes debinding and sintering to achieve the desired density and strength. This process enables the production of highly complex shapes and precise small parts that traditional manufacturing struggles to achieve efficiently.

In medical applications, the benefits are substantial. Metal injection molding medical technology is particularly suited for creating miniaturized, intricate, and durable components that are indispensable in surgical instruments, orthodontic devices, and drug delivery systems. MIM parts exhibit excellent material strength, corrosion resistance, and biocompatibility—critical factors for any medical-grade component. This ability to combine complexity with robust material properties makes MIM a game-changer in medical device manufacturing.

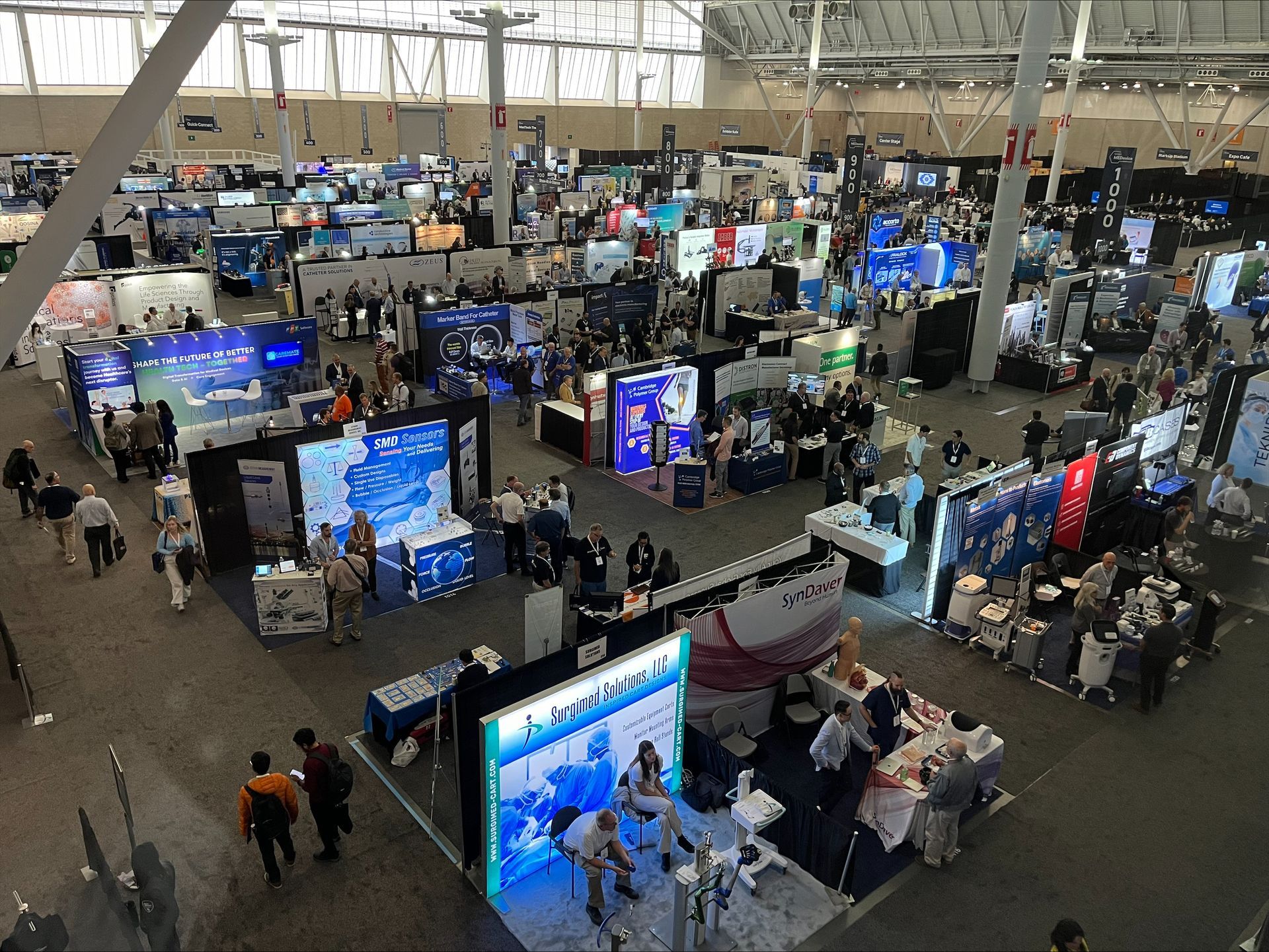

Why Boston Is a Growing Hub for the Metal Injection Molding Medical Industry

Boston, MA, is renowned worldwide as a medical and biotech powerhouse. The city’s numerous research institutions, hospitals, and cutting-edge companies fuel an ongoing demand for innovative medical components and devices. With this surge in innovation, metal injection molding medical technology in Boston, MA, is increasingly sought after as a method to meet the high-volume, high-precision needs of local manufacturers. This growing reliance on advanced manufacturing techniques underscores Boston’s commitment to pioneering medical advancements.

Boston’s medical device manufacturers require solutions that offer repeatable accuracy and cost efficiency without compromising quality. The precision and scalability offered by the metal injection molding medical process provide a competitive advantage, enabling local companies to bring new medical technologies to market faster. This environment of innovation and quality demand makes Boston an ideal location for advanced MIM services.

How Smith Metal Products Is Leading Metal Injection Molding Medical Technology in Boston, MA

Smith Metal Products has become a trusted partner for medical device manufacturers across Boston by harnessing the capabilities of the metal injection molding medical process in Boston, MA. Their expertise allows them to produce complex surgical instruments, orthodontic components, and intricate drug delivery system parts with unparalleled precision.

For example, surgical instrument designers often face challenges in achieving intricate shapes with lightweight materials that maintain strength and durability. Smith Metal Products uses metal injection molding medical techniques to manufacture these components cost-effectively while ensuring compliance with strict medical standards.

Orthodontic components, which demand biocompatibility and precise fit, also benefit substantially from Smith Metal Products’ MIM solutions. The company’s mastery of molding tiny, complex geometries ensures devices that improve patient outcomes and procedural efficiency.

Additionally, drug delivery systems require miniature parts that perform reliably without failure. Through metal injection molding medical techniques, Smith Metal Products delivers these sophisticated components consistently and at scale, helping innovators push the boundaries of pharmaceutical technology.

The Future of Medical Manufacturing With Metal Injection Molding Medical Techniques

As medical technologies continue to evolve, the demand for parts that combine complexity, performance, and affordability will only increase. MIM in the medical industry stands out as an indispensable manufacturing method capable of delivering on these needs. Boston’s status as a medical innovation hub will continue to drive growth and investment in precision molding technologies, reinforcing Smith Metal Products’ role as a leading provider. This momentum is expected to foster collaborations and innovations that further enhance medical manufacturing capabilities in the region.

Medical device manufacturers looking to capitalize on the next generation of tooling and components should consider metal injection molding medical technology as a primary solution. By leveraging this technology, companies can optimize product performance, reduce lead times, and scale production with confidence. The precision and reliability MIM offers will be crucial in meeting stricter medical regulations and increasing patient safety standards. Embracing metal injection molding medical in Boston, MA, empowers manufacturers to stay competitive in a fast-moving market and bring revolutionary healthcare solutions to life.

Transform Your Medical Device Manufacturing With Metal Injection Molding Medical Technology

If your business requires advanced medical components manufactured with pinpoint precision and durability, metal injection molding medical technology offers powerful advantages. Smith Metal Products is ready to help your company unlock these benefits. Contact Smith Metal Products today to discover how their expert metal injection molding medical services can transform your medical device manufacturing process and help you stay at the forefront of innovation. Don’t let manufacturing limitations hold your medical innovations back—embrace the future with metal injection molding medical in Boston, MA.