When it comes to metal fabrication in Washington, DC, companies and property owners alike must prioritize quality and expertise. Whether embarking on a commercial or industrial construction project, ensuring the metal components are fabricated and installed by seasoned professionals is critical to a successful outcome. Smith Metal Products, a trusted name serving Washington, DC, serves as a reliable example of what skilled craftsmanship and precise installation can achieve. This article delves into why professional metal fabrication is vital, highlighting structural integrity, safety compliance, and the nuances of local codes and permitting processes that only expert fabricators understand.

The Importance of Choosing Experts for Metal Fabrication

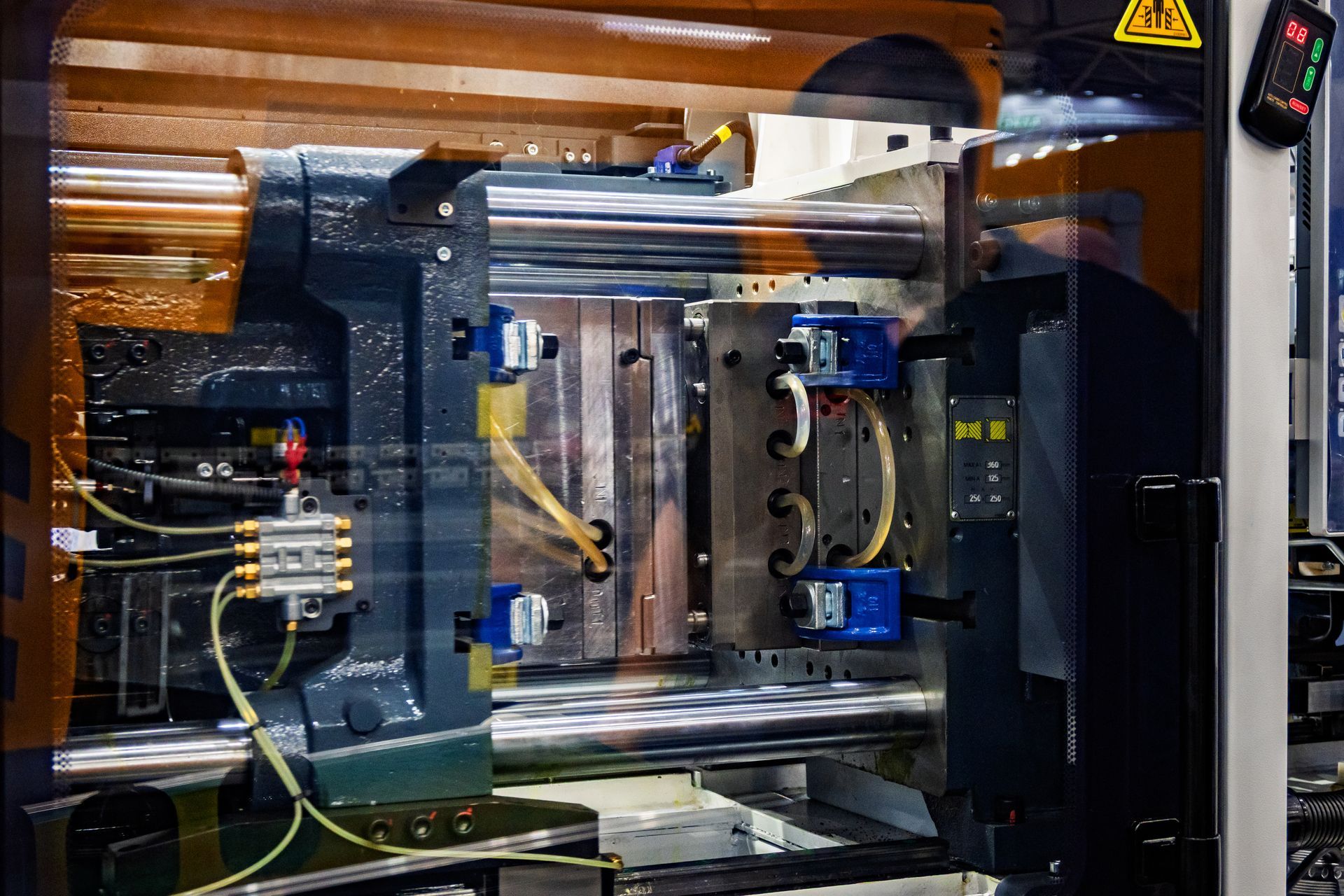

Metal fabrication is not merely about shaping metal; it’s about creating components that will withstand the test of time and usage, especially in commercial and industrial settings. Choosing professional metal fabrication guarantees that experienced fabricators apply the best practices, advanced technologies, and high-quality materials. Expertise in metal fabrication ensures that all dimensions, welds, and finishes meet exacting standards, preventing costly mistakes and future repairs.

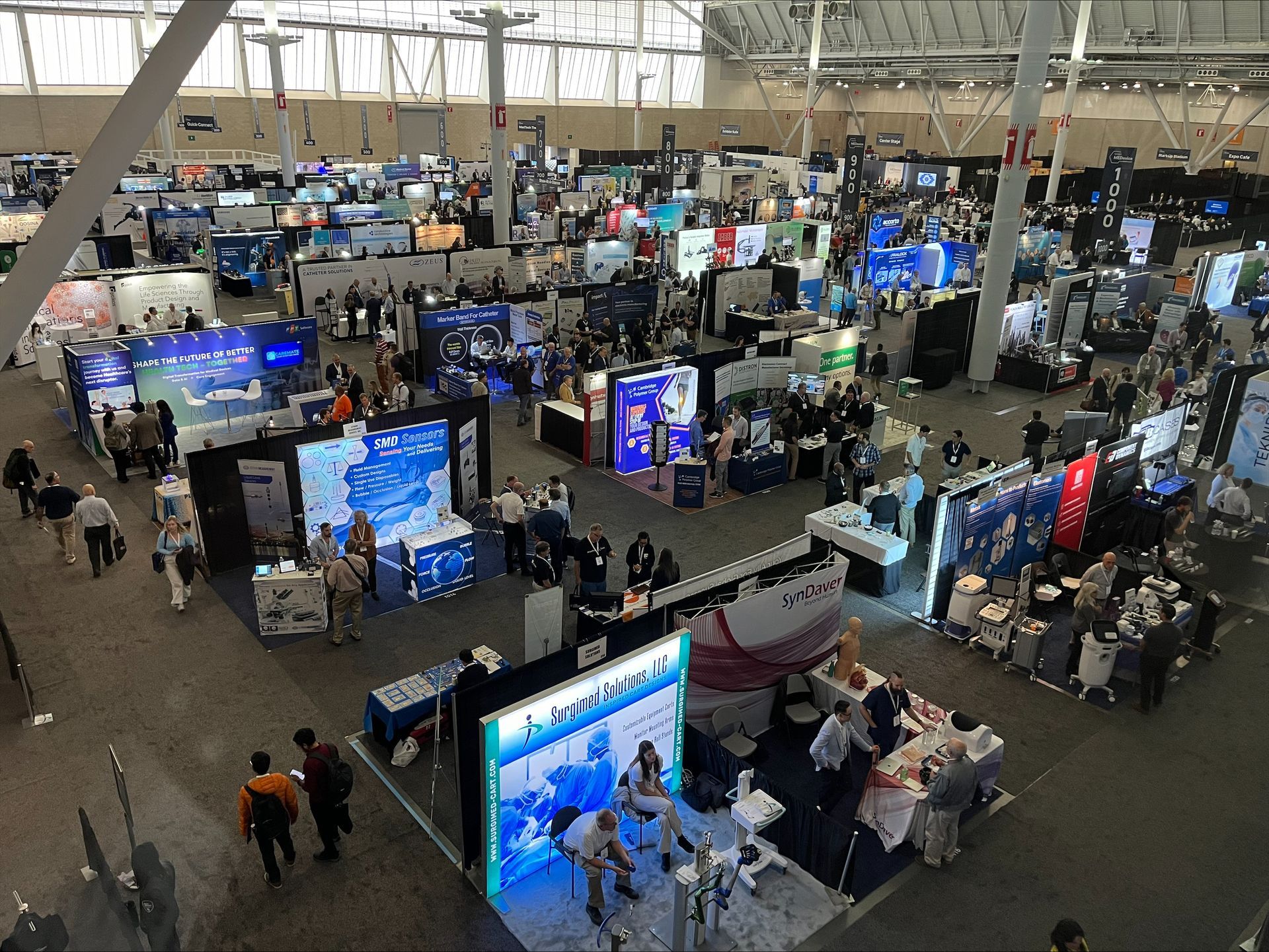

Commercial and industrial projects involve complex metal structures, such as beams, frames, staircases, and railings, where precision is non-negotiable. Without expert fabrication and installation, poor fits or weak joints can compromise the whole structure’s integrity, leading to safety risks and potential legal liabilities.

How Professional Installation Ensures Structural Integrity and Safety Compliance

Professional installation is just as critical as fabrication. When metal components are expertly installed, they uphold the structural design’s integrity and function as intended under load and stress. Washington, DC, projects demand adherence to rigorous safety standards, which only professionals with thorough knowledge of local building codes can ensure.

Safety compliance involves meeting national standards like OSHA regulations as well as local codes specific to DC. Proper installation of fabricated metal components reduces the risk of accidents like structural failure, falls, or fire hazards. Moreover, professional installers identify site-specific challenges early on, such as load distribution issues or environmental impacts, adapting their approach accordingly.

Long-Term Durability Through Skilled Fabrication and Installation

Durability in metal fabrication means resistance to wear, corrosion, and external stress over an extended period. Professional fabricators use certified materials and precise finishing techniques such as galvanizing or powder coating, which enhance longevity. Coupled with expert installation, these elements prevent premature deterioration and maintain performance.

Washington, DC’s climate, with its humidity and seasonal temperature shifts, can accelerate metal corrosion if not properly treated. Professional metal fabrication accounts for these factors and applies industry best practices to maximize the lifespan of metal structures, reducing maintenance frequency and overall costs.

The Cost Benefits of Professional Metal Fabrication and Installation

Investing in professional metal fabrication might seem like a higher upfront cost, but it offers significant long-term financial benefits that far outweigh initial expenses. Proper fabrication and installation reduce the likelihood of costly repairs, replacements, or project delays caused by errors or material defects. Experienced fabricators optimize material usage, minimizing waste and managing resources efficiently, which helps control project budgets.

Moreover, professional metal fabricators are well-versed in efficient project timelines, meaning commercial and industrial projects can avoid extended downtime or interruptions. This timely completion translates to savings in labor costs and allows businesses to start using their facilities sooner.

By ensuring compliance with stringent Washington, DC building codes and safety regulations, professional metal fabrication services also help avoid expensive fines or legal complications. In essence, partnering with seasoned fabricators safeguards your investment and supports a smoother, more cost-effective project lifecycle.

Navigating Building Codes, Permits, and DC-Specific Challenges

Washington has particular building codes and permitting processes that must be respected in metal fabrication projects. Professionals bring experience navigating these local regulations, ensuring that all metal works pass inspections and are legally compliant. This expertise avoids costly delays or reworks due to failed inspections or noncompliance.

Projects in Washington, DC, also face unique challenges, such as historic district restrictions or environmental requirements, that influence metal design and installation choices. Skilled fabricators work closely with architects, engineers, and regulatory bodies to craft solutions that meet aesthetic, environmental, and legal needs simultaneously.

Smith Metal Products: Experience You Can Rely On

Smith Metal Products exemplifies the value of experience and professionalism in metal fabrication in Washington, DC. Their expertise spans a wide range of custom fabrication services paired with precision installation, making them a trusted partner for complex commercial and industrial projects. Their team’s in-depth knowledge of local codes and regulations supports projects’ smooth completion while upholding the highest quality standards.

Secure Quality and Precision

Choosing professional metal fabrication in Washington, DC, goes beyond aesthetics; it’s an investment in safety, durability, and legal peace of mind. For projects that demand expert craftsmanship and adherence to local standards, partnering with experienced fabricators ensures success from start to finish. If you’re planning a custom metal fabrication project in Washington, DC, contact Smith Metal Products today for a consultation and experience firsthand the benefits of professional service tailored to your exact needs.