MIM Process Options

MIM Sintering

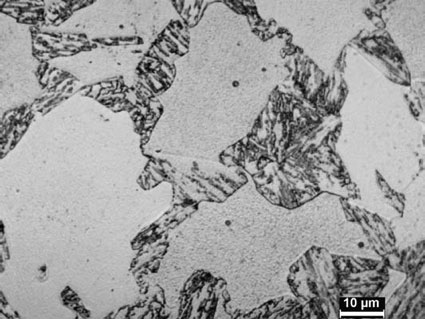

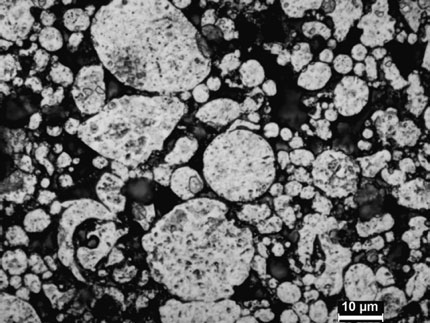

Final polymer extraction occurs during sintering. Sintering was used thousands of years ago to harden bricks or pottery by firing the shaped “green” ceramic body. The same idea is applied in MIM. Sintering changes a powder structure into a solid structure. This is illustrated below using optical microstructures taken from a 17-4 PH stainless steel powder during heating to 1000°C (1832°F) and then 1365°C (2460°F). In these pictures, the pore space previously occupied by binder appears black, and it disappears during heating.

Clearly sintering densifies the powder by removing the void space previously occupied by the binder. When properly performed, the sintered microstructure shows no evidence of the original powders and little porosity. The typical sintering shrinkage is from 17 to 21% on each dimension, nominally 21%, so the molded component is oversized to deliver the desired final dimensions.