Manufacturing Considerations

Ejection

Once the molded part has cooled it must be ejected. The ejection force depends on the contact area between the tooling and component, tool surface finish, coefficient of friction, and thermal contraction on cooling. Adhesive phases in the binder can cause sticking. A slight taper (or draft) in the tooling greatly aids in reducing ejection force; often just 0.5° is sufficient. Corners in the cavity are usually rounded for easier ejection; a radius of 0.2 mm (0.008″ inch) is satisfactory, but they can be as small as 0.05 mm (0.002″ inch).

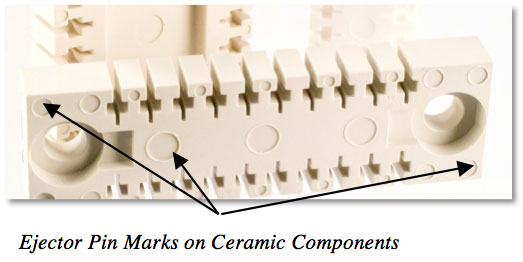

To eject the part, ejector pins push the part out of the cavity. Inserts, internal cores, threads, or any type of under-cut (trapped steel coring) must be retracted first to allow free ejection. Ejector pins leave witness lines on the component, since they concentrate the ejection force on a soft and often still warm molded shape. Larger pins are desirable to reduce the stress. The location and number of ejection pins depend on the component size, binder strength, and tooling complexity. Normally, the pins are placed to impress on noncritical locations and constitute more than 10% of the projected part surface.